Introduction

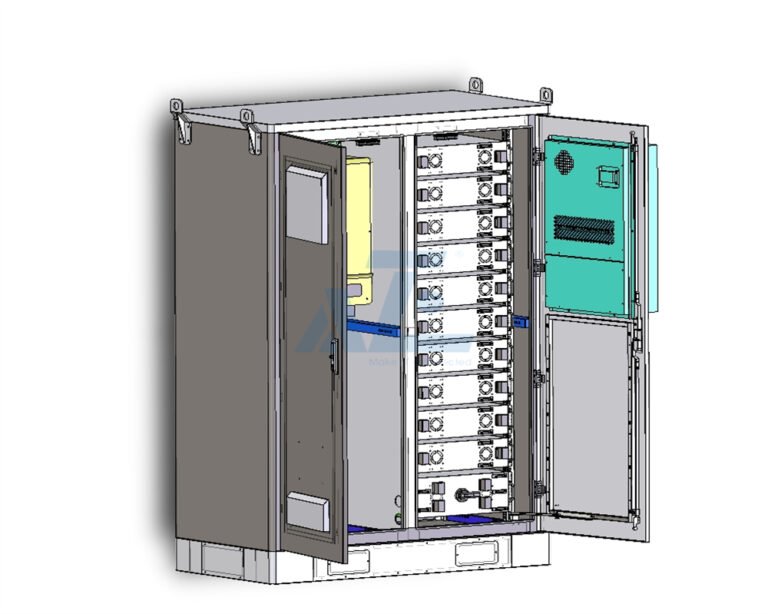

Standard battery enclosures may not always meet the specific requirements of energy storage projects. Many system integrators and EPC contractors require customized or OEM enclosure solutions to fit unique installation conditions, system architectures, and branding needs.

Common Customization Requirements

Structural Customization

- Rack-mounted, wall-mounted, or floor-standing designs

- Modular expansion capability

- Integration with inverters and control systems

Environmental Customization

- Higher IP ratings

- Special corrosion-resistant coatings

- Extreme temperature adaptation

Electrical & Functional Customization

- Customized cable entry positions

- Pre-installed grounding points

- Integrated cooling or heating components

Branding and Appearance

For commercial projects, enclosures may include:

- Customized colors

- Logo printing

- Consistent industrial design language

OEM Design Process

- Requirement analysis

- Structural and thermal simulation

- Prototype manufacturing

- Testing and certification

- Mass production

SEO Keywords

LiFePO₄ battery OEM enclosure, customized lithium battery housing, energy storage battery cabinet design

Conclusion

Customized enclosure solutions provide greater flexibility, better system integration, and higher project success rates for LiFePO₄ energy storage systems.