Meta description: Learn ESS cabinet design for LiFePO₄ systems: modular layout, ventilation, AC/DC isolation, monitoring, fire suppression integration and maintainability strategies.

Keywords: LiFePO4 ESS cabinet, ESS design, battery rack layout, energy storage cabinet

Intro

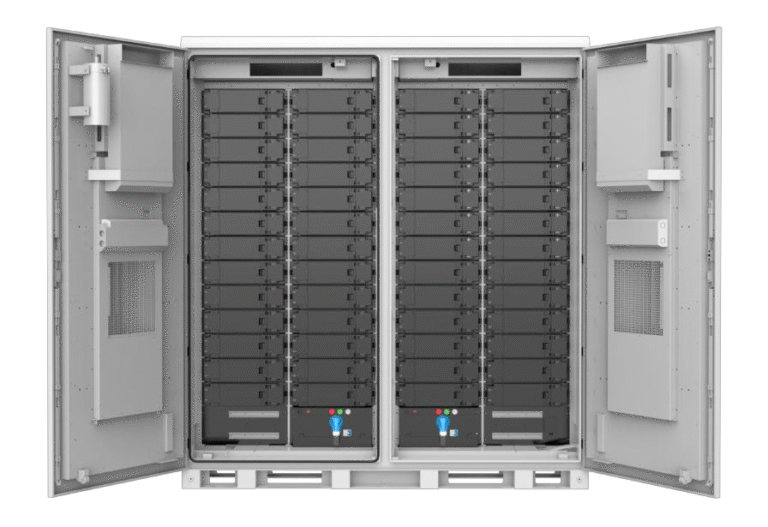

An ESS cabinet integrates batteries, BMS, power electronics and safety systems. Proper cabinet architecture reduces installation time, improves serviceability and minimizes operational risk. This article covers layout strategies, cabling routes, thermal design, AC/DC segregation, grounding, monitoring placement and practical safety measures for LiFePO₄ cabinets.

Recommended Cabinet Layout

- Top-to-bottom flow: Power electronics (inverter/charger) typically top (heat-producing), battery modules mid, cable/AC terminations bottom (or vice versa depending on access).

- Clear separation: Maintain physical segregation between DC battery modules and AC inverter sections to reduce arcing risk. Use metal partitioning and insulated barriers.

Ventilation & Thermal Management

- Forced-air ventilation: Fans with dust filters and controlled airflow paths.

- Heat exchangers / split units: For high-density commercial cabinets, integrate dedicated HVAC for temperature control.

- Thermal zoning: Use sensors to control fans, alarm if temperature gradient exceeds X°C (typical alarm at 5–8°C delta).

Electrical Design & Safety Components

- Busbar & DC isolation: Main DC busbar with accessible DC isolator/maintenance switch and a visible disconnect.

- Fusing & DC breakers: Per-module or per-string fuses; select fast-acting UL-rated components.

- Earthing & grounding: Single-point grounding scheme to avoid ground loops; lightning protection in outdoor installations.

- Surge protection devices (SPDs): On AC and DC sides.

Monitoring, Maintenance Access & Serviceability

- BMS gateway placement: Accessible CAN/communication ports for diagnostics.

- Cable routing: Use cable trays and clear labeling. Include hot-swap capabilities for modules if required.

- Access panels & maintenance door: Lockable but easy-to-open for technicians; include interlocks for safe service.

Fire Detection & Suppression Integration

- Early detection: Smoke/particle detectors inside cabinet with alarm integration to BMS and site alarm.

- Suppression: Pre-action sprinkler or gaseous suppression typically outside the cabinet; in-cabinet gaseous suppression is complex — prefer compartmentalized fire barriers and active cooling.

- Automatic disconnect: On confirmed fire detection, BMS triggers contactor open and signals site fire system.

Environmental & Installation Considerations

- IP rating & drainage: For outdoor cabinets, ensure condensation control and drainage provisions.

- Seismic & vibration mounts: Use shock mounts depending on local regulation and installation conditions.

- Transport & lifting points: For heavy racks, include certified lifting eyes and forklift pockets.

Conclusion

Thoughtful ESS cabinet design improves lifespan, maintains safe operation and reduces O&M costs. Integrate electrical, thermal and fire-safety design early in system architecture to avoid expensive retrofits.