Meta description: Best practices for LiFePO₄ pack interconnects: busbar materials, welding vs bolting, current path design, fusing, and thermal stress mitigation.

Keywords: battery busbar design, LiFePO4 wiring, cell interconnects, welding parameters

Intro

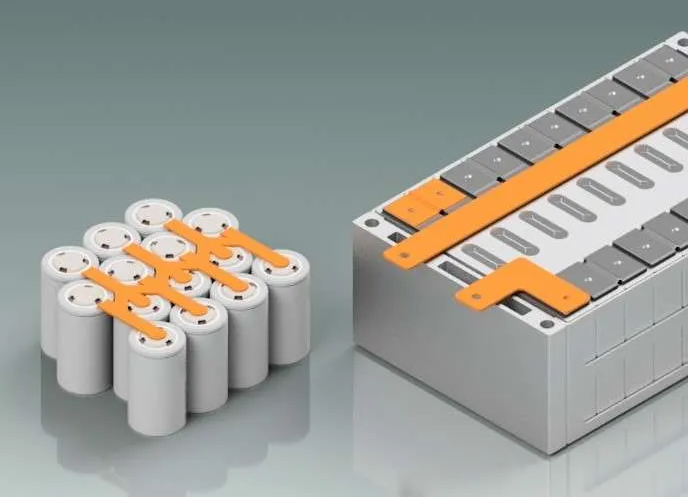

The way cells are electrically connected impacts resistance, heat generation and reliability. Poorly sized conductors or flawed welding processes cause hotspots and premature failures. This article details conductor choices, busbar designs, welding best practices and electrical safety devices used in LiFePO₄ packs.

Conductor & Busbar Materials

- Copper: High conductivity (preferred for low-voltage/high-current paths).

- Nickel-plated steel / nickel strips: Common for cylindrical and some prismatic packs because of weldability and corrosion resistance.

- Aluminum busbars: Lighter, used at higher voltages; require anti-oxidation treatment when bolted.

Connection Methods & Tradeoffs

- Welding (laser/ultrasonic/resistance): Low-resistance, permanent; requires process control to avoid thermal damage.

- Bolted busbars with flexible shunts: Easier to service but can loosen and increase R over time; use proper torque specs and locking washers.

- Soldering: Not recommended for high-current primary paths due to mechanical stress on solder joints.

Thermal & Mechanical Stress Considerations

- Incorporate flexible connectors or braided straps to accommodate thermal expansion.

- Ensure enough thickness and cross-sectional area of busbar to limit I²R losses. Example: for a 100 A continuous current, conductor cross-section should be sized for <1% voltage drop and <5°C rise in junction — consult standard cable sizing tables.

Fuses, Current Sensors & Protection

- Add cell-group fuses or PTC (positive temperature coefficient) devices to limit fault currents.

- Place current sensor (shunt or Hall effect) centrally for accurate SOC estimation and BMS protection.

Testing & QA Practices

- Perform four-wire resistance measurements for busbars after assembly.

- Thermal imaging under load to detect hotspots.

- Vibration testing for bolted connections.